SEARCHING FOR A QUICK ANSWER?

Listed below are the most frequently asked questions:

How much force is required to process 25mm shipbuilding panels?

How much force is required to process 25mm shipbuilding panels?

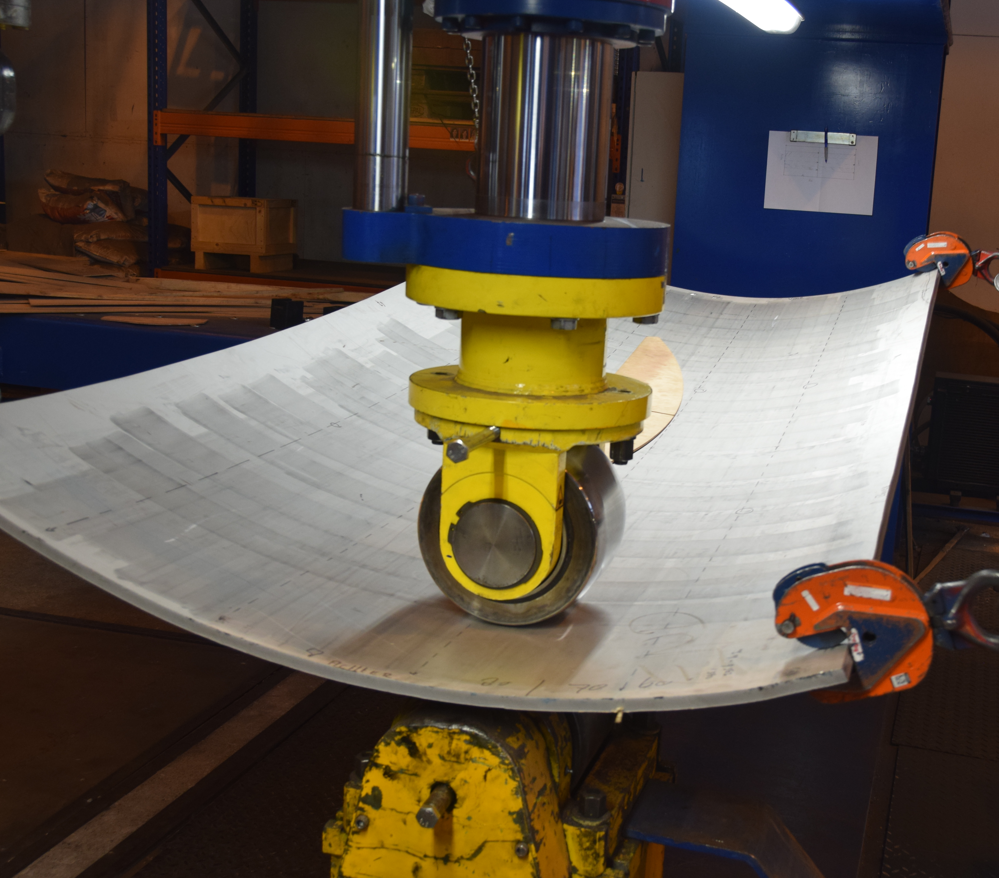

You can calculate with the rule of thumb that 12 ton per mm thickness is needed to shape a Grade A shipbuilding panel. However there can be many execptions to this rule, contact us to learn what would be needed for your situation.

How do I determine which solution is the best for me?

How do I determine which solution is the best for me?

Our sales consultants are available to guide you through this process. Based on factual data from your production, growth plans and ambitions they will be able to calculate what would be the optimal solution for you.

Why do you offer presses ranging from 275 to 1500 ton when the rolling unit always generates maximum 150 ton rolling force?

Why do you offer presses ranging from 275 to 1500 ton when the rolling unit always generates maximum 150 ton rolling force?

Why do you offer presses ranging from 275 to 1500 ton, when the rolling unit always generates a maximum 150 ton rolling force?

Rolling is effective for panels up to 30-35 mm thick. Panels above this thickness require higher bending forces. As Nieland’s SBP shipbuilding press can be equipped with multiple tools, thicker panels can be stretched using the stretching stamps. This allows you to have one solution, one shipbuilding press that can effectively shape panels of a wide variety of thicknesses.

How long will it take to be a professional cold forming operator?

How long will it take to be a professional cold forming operator?

After Nieland’s 12 weeks on site training, the operator will be able to work independently and create the required shape of complex hull panels. By using the Shipbuilding Press the operator will improve in efficiency reaching maximum effectiveness in 12-18 months. (Depending on previous experience.)

Are the integrated cranes always part of the contract?

Are the integrated cranes always part of the contract?

Nearly always, yes, because the cranes have to comply with Nieland’s specifications. We integrate our Shipbuilding Press with cranes to ensure an effortless installation and use of the equipment.

What is the lead time of a new press?

What is the lead time of a new press?

On average we work to a minimum of 20 weeks (excluding shipment), but this depends on our current order book. Please contact us to discuss your timelines and see how we can meet them.

How will local mounting and commissioning be accomplished?

How will local mounting and commissioning be accomplished?

Nieland’s service team will perform the installation and commissioning. In most cases two specialists will perform the work with some support from your local team of technicians.

Can’t find the answer you’re looking for?

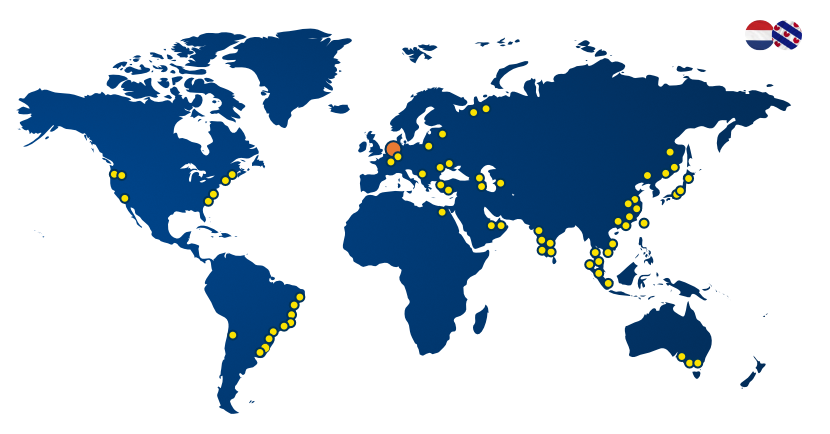

300+ installations in 23 different countries

Premium quality from The Netherlands

Over the years, Nieland has become the worldwide market leader in cold forming. We distinguish ourselves with turnkey solutions that include a press with full compliance, the transfer of knowledge and all other support needed to secure smooth implementation. All our products are designed and built in The Netherlands.