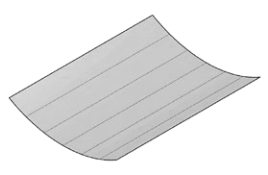

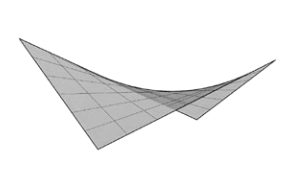

1.5 x 3 m

25 mm

5 hours

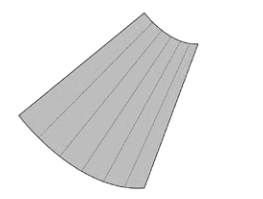

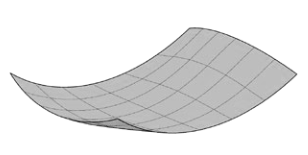

2.5 x 8 m

20 mm

3 hours

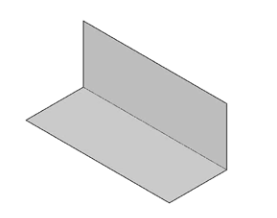

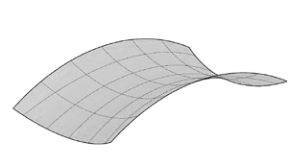

0.5 x 3 m

25 mm

1.5 hours

Panel curving

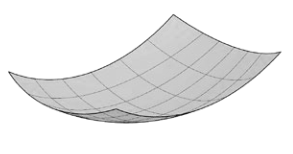

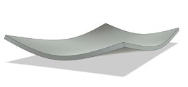

- One Nieland press can produce single curved panels and double curved panels (fig. 4, 5, 6, 7).

- For the developable panels (fig. 1, 2, 3) the bending tools are used on the Nieland press.

- For the non-developable, double curved panels (fig. 4, 5, 6, 7) the operator will use a combination of the Nieland bending and stretching tools.

- For stretching, the rolling unit PWU is used which will generate the required elongation to curve a panel.

- The required shape is achieved in an efficient way.

Cold forming is 8 times faster than line heating

- Reduces time

- Is more accurate

- Lower costs

NIELAND’S COLD FORMING TECHNOLOGY PRODUCES DOUBLE CURVED HULL PANELS 8 TIMES FASTER THAN LINE HEATING

The production of double curved hull panels, like bulbous, saddle and twisted shapes, can be a major challenge for many shipyards.

We know you desire a shorter production time, accurate and controlled shapes, with no impact on the material properties and an overall cost reduction.

Cold forming uses the combination of bending and stretching and Nieland offers this in one single press. We pride ourselves in being the worldwide market leader in Cold Forming Technology, and in providing a tailored solution to your needs.

Shaping

the future

Training

Our trainers are specialists in cold forming technology. They will provide on-site training for a three-month period, using actual production panels, from day one. After this training period the operators are ready to create the required shapes of panels.