Cold forming by a rolling unit

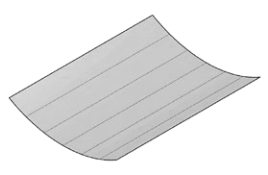

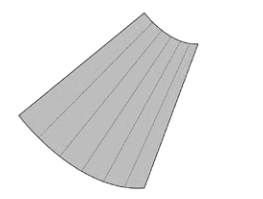

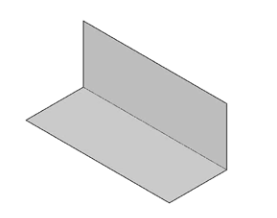

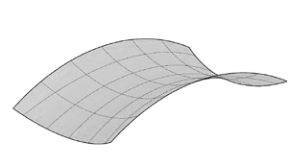

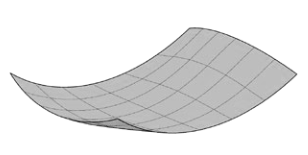

Cold forming is based on stretching certain areas on the plate by means of a rolling unit. This elongates designated lines on the plate. For basic applications in cold forming, the panels 1-3 can be shaped on any conventional press brake. Please note panels 1-3 are called “developable panels” which means they do not need to be stretched in order to achieve the required shape. Bending only will be sufficient.

Non-developable panels

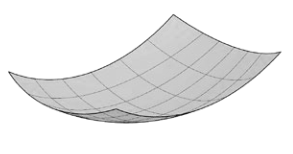

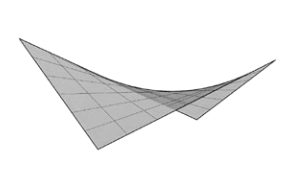

The key issue when shaping compound curvature panels, like panels 4-7, is that certain lines need to be stretched by rolling in order to achieve the required compound curvatures. These panels are called “non-developable panels.”

Stretching and bending

Panels 4-7 need the combination of stretching (by rolling) and bending. One single Shipbuilding Press from the Nieland SBP series, can do it all.

Training

Operator training is managed on site by one of Nieland’s cold forming specialist-trainers during a three-month training period plus a one-month re-training after one year.